Safety & Health

- Sustainability

- Social

- Safety & Health

Vision & Strategy

Hyosung Heavy Industries' Power & Industrial Systems division has established a vision and strategic objectives in an effort to create a safe and healthy work environment.

EHS Policy

Hyosung Heavy Industries' Power & Industrial Systems division is dedicated to fulfilling its social responsibilities with respect for humanity,

and environmental preservation, in order to build customers trust and work our way to the top of this company,

we comply with the following HSE policies.

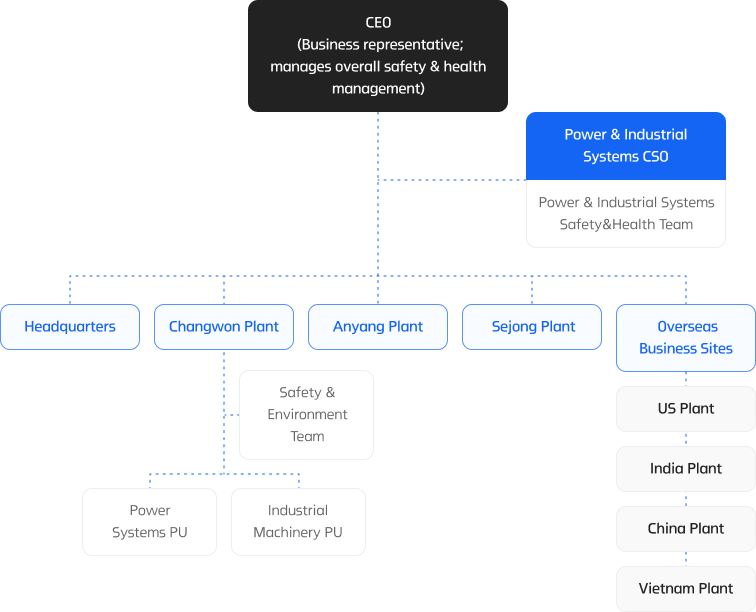

Organization

Activities

Operation of the safety & health management system

|

Operation of the safety and health system management (ISO 45001, KOSHA-MS) |

The Power & Industrial Systems division of Hyosung Heavy Industries is operating ISO 45001 and KOSHA-MS to establish the safety and health system. |

|---|---|

| Safety and health-related laws audit and improvement support |

In order to prevent safety accidents and legal violations in advance, we support inspecting and improving through Audit of the matters of safety and health-related laws such as the Serious Accidents Punishment Act and the Occupational Safety And Health Act, etc. |

| Health and safety budget establishment and execution |

We prepare the budget necessary for accident prevention and improvement of harmful and risk factors and check whether it is executed properly. |

| Selection and management of qualified suppliers |

We select suppliers with safety and health capabilities through evaluation from the contract stage and continuously manage them through regular evaluations (once/semi-annually). |

Workplace management

| Domestic/overseas workplaces and installation site safety inspection and guidance |

Domestic/overseas workplaces are regularly inspected for improvement and guidance. In particular, the Representative Director personally visits the site at least once a half year to check the safety management status and support improvement. |

|---|---|

| Activation of workplace risk assessment |

Risk assessment, which is the key to establishing the self-discipline prevention system, is activated, and safety accidents are prevented by fundamentally improving identified risk factors. |

| Thorough accident investigation and establishment of recurrence prevention measures |

In the event of a safety accident, we prevent similar accidents by establishing thorough measures to prevent recurrence and conducting horizontal deployment through specialized techniques such as RCA, etc. |

| Audit for compliance status with the 10 Safety Golden Rules |

Hyosung Heavy Industries' Power & Industrial Systems PG established 10 safety golden rules, and distributed them to workplaces and installation sites. In addition, we regularly check compliance with the Safety Golden Rules and provide support for improvement. |

Reinforcement of safety competency

| Educational support for competency improvement |

We are reinforcing the competency of safety managers through various educational programs such as safety leadership for supervisors and safety education instructor training courses, etc. |

|---|---|

| Competency-based safety and health manpower placement |

Safety and health personnel, such as safety managers and health managers, who are not just qualified with legal requirements, but with safety and health competency are placed and managed at the workplace. |

| Safety Knowledge training and skill guidance |

16 pieces of knowledge (company vision, understanding of accident investigation, etc.) and 16 skills (regulation preparation, accident initial response skill, etc.) are being taught to strengthen the competencies of safety-related personnel. |

| Distribution of safety inspection white paper & guidebook |

The safety inspection white paper summarizing the main points pointed out at the site and the guidebook summarizing the main safety rules and legal matters to be observed at the site are distributed and used as educational materials to prevent safety accidents. |

Safety Golden Rules

Hyosung Heavy Industries selects and manages 10 Golden Safety Rules to establish site-specific safe work environments.

-

No passage under

heavy loads -

No work before

approval -

No release of safety

devices -

No unauthorized access to

operating equipment -

No cell phone during work,

driving, and walking

-

Use designated

protective

equipment -

Measure oxygen

concentration in

confined spaces -

Use safety

harness when

working at height -

Secure safe

passage within

work zones -

Attach safety

signs to

equipment under

maintenance/repair