Brand Journalism

- Brand

- Brand Now

- Brand Journalism

Brand Journalism

The Arrival of the Power Super-cycle: The Core of K-Transformers

2024.11.11

The advancement of the artificial intelligence (AI) industry has generated new power demands. As AI data centers emerge globally, from the U.S. to Europe to China, the demand for power lines and power grids has surged to meet electricity supply needs. According to the International Energy Agency (IEA), data center electricity consumption is expected to double by 2026, and global power demand is projected to increase by an average of 3.4% per year. Coupled with factors such as extreme weather, the expansion of renewable energy generation facilities, the aging of transmission and distribution infrastructure, and the growing adoption of electric vehicles, investments in power infrastructure are set to rise significantly. Experts predict that the global power equipment market will enter a massive boom period known as the " Super-cycle" over the next decade.

The True Value of K-Transformers Shining in the Super-cycle

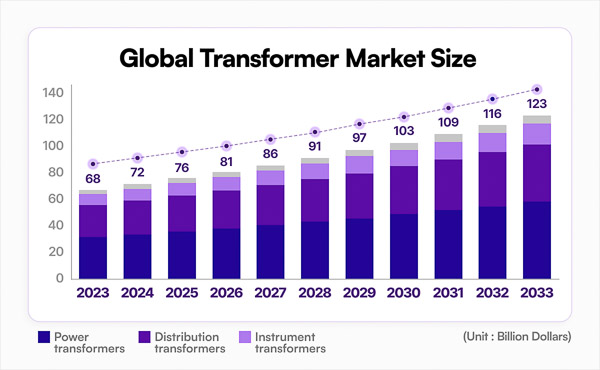

The power Super-cycle refers to a trend in the power industry characterized by long-term increases in demand and expanded investments. This trend is driving up the demand for highly efficient transformers, which are key equipment ensuring the stability and efficiency of power grids. Transformers play a crucial role in regulating voltage as electrical energy travels from power plants to consumers. Market research firm Market.us forecasts that the global transformer market, valued at USD 68 billion in 2023, will grow at an average annual rate of 6.2%, reaching USD 123 billion by 2033.

▲ Market research firm Market.us forecasts that the global transformer market Source: Market.us (January 2023)

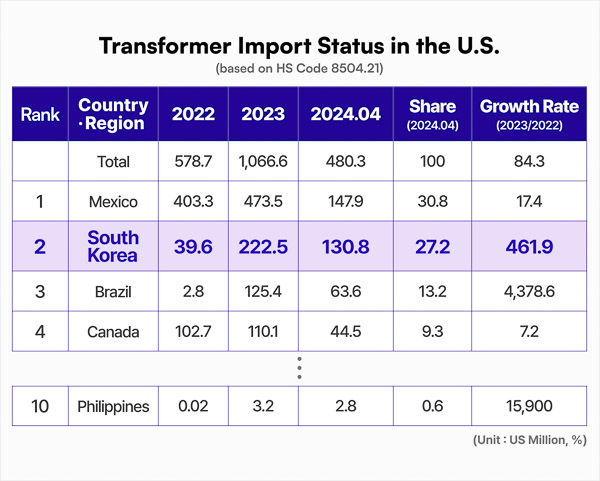

As the super-cycle takes hold, transformers from South Korea have become a significant export success. According to the Korea International Trade Association, transformer exports increased by 81.8% year-on-year in the first quarter of 2024, following an 84.1% growth rate in 2022. By July 2024, cumulative transformer exports are expected to reach approximately KRW 1.3786 trillion, which is already 87% of last year's export total. This growth trend is anticipated to continue, with expectations for record-high performance this year. Hyosung Heavy Industries is at the forefront of these achievements.

Why Hyosung Heavy Industries' Power Solutions are in Demand Worldwide

What makes Hyosung Heavy Industries recognized in the power market? Its outstanding technological capabilities, combined with extensive experience in global projects and sustainable solutions, contribute to this recognition. Currently, transformer trends emphasize sustainability, low noise, and low losses. In these areas, HYOSUNG’s high-efficiency ultra-high voltage transformers and power solutions are among the best in the world.

▲ A new type of transformer insulated with biodegradable plant oil or sustainable synthetic oil (Learn more)

Since developing Korea's first 154kV ultra-high voltage transformer in 1969, Hyosung Heavy Industries has led the field by introducing 345kV and 765kV transformers as the first in the industry. Furthermore, it is one of the few transformer manufacturers globally capable of supplying specialized transformers requiring advanced technology, such as plant oil-insulated transformers for enhanced eco-friendliness and phase-shifting transformers for interconnecting grids between countries.

As a result, HYOSUNG’s ultra-high voltage transformers are recognized for their performance and capabilities in over 70 countries. The customized solutions, designed, manufactured, and tested to meet the specific regional, industrial, and application needs of each country, have received positive feedback. Since beginning transformer exports in the 1970s, HYOSUNG has participated in large-scale power infrastructure projects in major markets such as the U.S., Europe, and Australia, demonstrating their capabilities even in challenging environments like deserts and saline areas with tailored designs.

▲ Hyosung Heavy Industries' ultra-high voltage transformer factory, 'HYOSUNG HICO,' in the United States.

At the Changwon plant alone, more than 7,500 ultra-high voltage transformers have been produced, and the company has expanded its production network by establishing local manufacturing bases in Tennessee, USA, and Jiangsu, China, which is expected to further contribute to the development of the global power grid.

Hyosung Heavy Industries is advancing beyond transformer technology into cutting-edge solutions that incorporate Energy Storage Systems (ESS) and High Voltage Direct Current (HVDC) technology, supporting the spread of renewable energy and future-oriented power management. HVDC is a key technology for the next-generation power transmission and distribution market that is set to change the landscape of electricity. In July 2024, the company developed a 200MW voltage-source HVDC, marking the first domestic independent development and becoming the fifth globally to achieve local production of this technology. The power equipment asset management solutions, which combine internet-based information technology and operational technology, ‘ARMOUR’ and ‘ARPS,’ are also gaining attention as sustainable future power systems.

▲ HVDC demonstration facility where Hyosung Heavy Industries is cultivating advanced power technology

Hyosung Heavy Industries' Leadership in the Global Power Grid

The United States is a major import market for domestic transformers, accounting for 40% of total exports. To improve the aging power grid, the U.S. government announced a large-scale investment plan. Under the Infrastructure Investment and Jobs Act (IIJA), effective from 2021, the government plans to invest USD 1.2 trillion in social infrastructure, including railways, roads, water supply, and power networks, over the next ten years.

Hyosung Heavy Industries established a U.S. subsidiary in Pittsburgh in 2001 and has positioned itself as a leading transformer supplier by selling ultra-high voltage transformers. Seizing the opportunity presented by high demand in the U.S., the company secured a production base for ultra-high voltage transformers in Memphis, Tennessee, in 2020. Hyosung Heavy Industries plans to double its production capacity by adding new testing and manufacturing facilities.

▲ Transformer Import Status in the U.S. (based on HS Code 8504.21) Source: Global Trade Atlas (June 2024)

Hyosung Heavy Industries' flagship product, transformers rated at 100 MVA and above, are classified as Large Power Transformers (LPT) in the United States, where they account for 90% of local transmission and distribution power. Currently, 70% of the installed LPTs in the U.S. are over 25 years old, which is notable considering that the typical lifespan of a large transformer is around 30 to 40 years. As such, HYOSUNG is devising strategies to target the reinforcement of the power grid and new expansions.

India is also the third-largest electricity consumer in the world and suffers from a power supply-demand imbalance. According to the International Energy Agency's "Electricity 2024" annual report, electricity demand is expected to increase by more than 6% per year until 2026.

HYOSUNG is positioning India as a strategic hub for the Asian market, expanding its production facilities and establishing a stable supply chain. In 2015, the company set up a manufacturing subsidiary in Pune, Maharashtra, and built a high-voltage circuit breaker GIS factory the following year. This facility was the first circuit breaker plant constructed by Hyosung Heavy Industries overseas, becoming a key base for power infrastructure in India, South Asia, and the Middle East.

▲ In July 2024, Hyosung Heavy Industries became a key supplier for Australia’s renewable energy transmission infrastructure project with a transformer supply contract worth KRW 35 billion.

Meanwhile, the company is also strengthening its presence in Europe, Australia, and Africa with notable achievements. In 2010, HYOSUNG was selected as the primary supplier of high-voltage transformers for the UK Power Networks, making its entry into the local market, and has gradually expanded its market share in Europe. Recently, the company won a contract for a large-scale phase-shifting transformer project with the UK’s National Grid, demonstrating its prowess in the specialized transformer sector.

Since entering Norway in 2020, Hyosung Heavy Industries succeeded in securing a contract for high-voltage transformers from the state-owned transmission company Statnett in July 2024, marking its largest order yet. The company’s market share in Norway's high-voltage transformer market has reached 80%. Additionally, the company has established an R&D center for sustainable power equipment in Europe to lead technology development.

Hyosung Heavy Industries plans to significantly increase its high-voltage transformer production capacity by investing KRW 100 billion in both South Korea and Memphis, USA. Such bold investment is essential to reliably supply the long-term orders already secured and to respond to the super-cycle expected to last over ten years. As a top-class supplier, Hyosung Heavy Industries is unhesitant to take on challenges in order to provide sustainable, high-quality products.

At the center of the power super-cycle, Hyosung Heavy Industries' transformers are responsible for the backbone networks of many countries. With a proactive approach, the company has swiftly modernized the global power grid in response to soaring electricity demand. The company's efforts to develop next-generation markets is now bearing fruit as the company enters this super-cycle. This is why Hyosung Heavy Industries is anticipated to solidify its position as a leader in power solutions while ushering in new waves across the globe.