Brand Journalism

- Brand

- Brand Now

- Brand Journalism

Brand Journalism

Hyosung Heavy Industries' Technology and Future Prospects at SIEF 2023

2024.04.22

Hyosung Heavy Industries participated in the Korea Electric Industry Exhibition (Seoul International Electric Fair, SIEF), the largest energy and power generation exhibition in South Korea. Held at COEX A and B halls in Samseong-dong, Gangnam-gu, Seoul from October 18 to 20, SIEF 2023 marked its 27th year as an energy-related exhibition. This year, under the slogan "Energy Solution Leader for Tomorrow," Hyosung Heavy Industries showcased its power-related equipment, asset management systems and ESG strategies.

▲ The entrance of SIEF 2023 exhibition hall

Upon entering the Hyosung Heavy Industries exhibition hall, the first thing that caught the eye was a huge media facade set up in the middle of the venue. At SIEF 2023, Hyosung Heavy Industries actively used this media facade to widely promote its ESG brand "RE:GEN NEW ENERGY".

▲ Hyosung Heavy Industries Exhibition Hall's Central Media Facade Draws Attention with 3D Representation of Marine Life

The media facade of Hyosung Heavy Industries' exhibition hall showcased various energy solutions that have attracted great attention in the industrial sector. The most captivating was the video related to Hyosung Heavy Industries' ESG brand 'RE:GEN NEW ENERGY'. Especially the 3D animation with turtles and dolphins attracted the admiration and attention of many visitors at the event.

ARMOUR Solution: Understanding and protecting power equipment

Another highlight of the exhibition was the ARMOUR (Asset Remote Management System for Operational Utility's Reliability) display, which showcased the pinnacle of Hyosung Heavy Industries' technological expertise. ARMOUR is an asset management system developed by Hyosung Heavy Industries for power plants and substations. Its ultimate goal is to assess the current operating status of power equipment, predict its lifetime, and maintain it for accident-free operation.

ARMOUR provides customers with accurate equipment life model curves based on an AI solution built from over 20,000 types of diverse data collected through inspection and maintenance of power plant and substation systems since 1982. ARMOUR can objectively assess and diagnose the condition of equipment more accurately than experienced engineers. As a result, it not only supports maintenance, but also extends equipment life and reduces costs.

▲ Visitors learn about ARMOUR solution

Hyosung Heavy Industries is currently developing an integrated power equipment monitoring system that combines ARMOUR with a preventive diagnostics system. Expected to be completed in 2024, this system is expected to become the bible of integrated power equipment monitoring and maintenance systems worldwide, leading the global market.

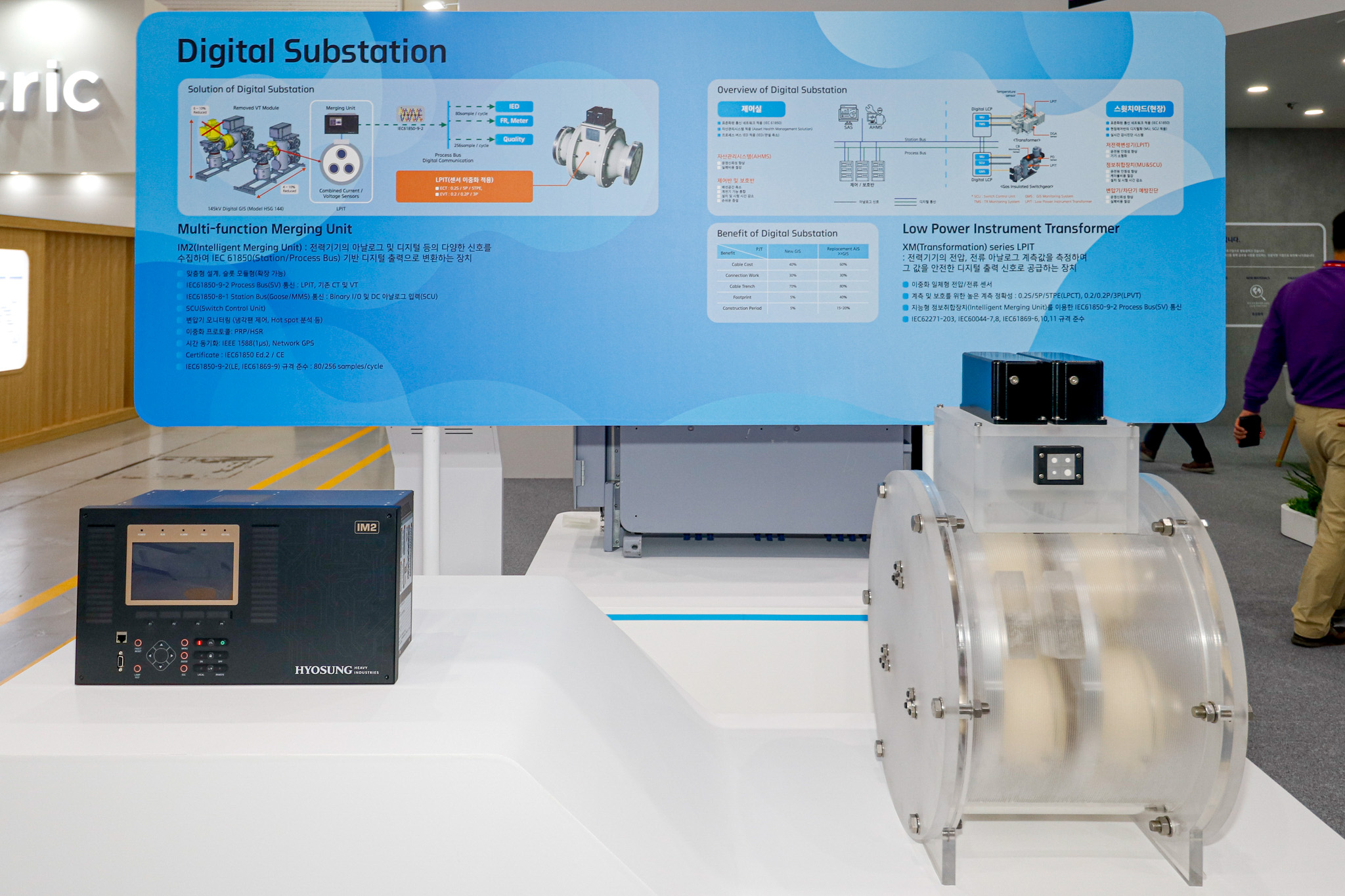

Digital substation: Converting diverse signals into digital form

To take full advantage of the ARMOUR solution, status data from various parts of the plant is required. This data helps to identify abnormal signals or early symptoms of problems. After introducing the ARMOUR solution in the Hyosung Heavy Industries exhibition hall, the next section introduced the Digital Substation system, which is capable of detecting and transmitting abnormal signals from various parts of the equipment.

Digital Substation equipment is a monitoring/protection device that can be used in indoor and outdoor power plants or substations. Installed in various substation equipment such as GIS (Gas Insulated Switchgear), transformers, and circuit breakers, Digital Substation collects data generated from each piece of equipment, detects any abnormalities, and notifies the customer. Based on this data, customers can determine the aging status and anomalies of their equipment, ensuring the protection of substation assets and personnel.

▲ Digital substation transmits operational monitoring signals in digital form

Digital substation equipment is divided into Low Power Instrument Transfer (LPIT) and Merging Units. LPIT converts all analog/digital signals generated by the equipment into a digital format for transmission to the analyzer. The merging unit then takes the data from the LPIT and transfers it to predictive diagnostic/asset management systems such as ARMOUR.

The heart of high-capacity power transmission: HVDC

In addition, visitors to the Hyosung Heavy Industries exhibition were able to explore the core technology of HVDC (High Voltage Direct Current) that Hyosung Heavy Industries possesses. Most power plants, except for certain special cases such as solar power generation, produce alternating current (AC) electricity. When AC power is transmitted externally, it is converted to high-voltage direct current (DC) to minimize power loss. DC transmission also has the advantage of being easier to maintain. The system that converts AC electricity generated in power plants into high-voltage DC for transmission is known as HVDC. Systems that transmit over 100 kV are called HVDC, those with DC voltages between 10-20 kV to below 100 kV are called MVDC, and those below 10 kV are called LVDC.

▲ Hyosung Heavy Industries' HVDC MMC Module

In HVDC, stable power conversion devices are critical. Connecting multiple Modular Multilevel Converter (MMC) modules in series to convert and transmit high-voltage DC is known for its adaptability and efficiency.

Hyosung Heavy Industries' MMC is known for its exceptional stability. A recent application was a 200 MV substation in Yangju, Gyeonggi Province, where approximately 1,200 Hyosung Heavy Industries MMC modules were used. In addition, Hyosung Heavy Industries will provide HVDC solutions for the West Coast Backbone Project, part of the HVDC backbone network project initiated by Korea Electric Power Corporation to meet future power system needs.

Improving power quality and stability with STATCOM

Hyosung Heavy Industries' STATCOM (STATic synchronous COMpensator) was another highlight of the exhibition that attracted great attention from visitors. STATCOM is a device that maximizes the transmission capacity of lines while maintaining the safety and utility of power systems. It is used in conjunction with power companies to compensate for reactive power, ensure system stability and increase transmission capacity. In renewable power plants, especially wind farms, STATCOM is used to comply with fault ride through regulations and to provide reactive power capacity. It is also used in industrial facilities to balance the current in electrical loads with momentary high power, such as large motor loads at startup, and to improve the power factor in factories.

▲ Miniature of Hyosung Heavy Industries STATCOM equipment

Known for its excellent stability and durability, Hyosung Heavy Industries' STATCOM, like its HVDC equipment, utilizes MMC technology for easy scalability to large capacities. Currently, Hyosung Heavy Industries' STATCOM can be installed with a single capacity of up to ±500Mva.

Experience Hyosung Heavy Industries' technological expertise through various media objects

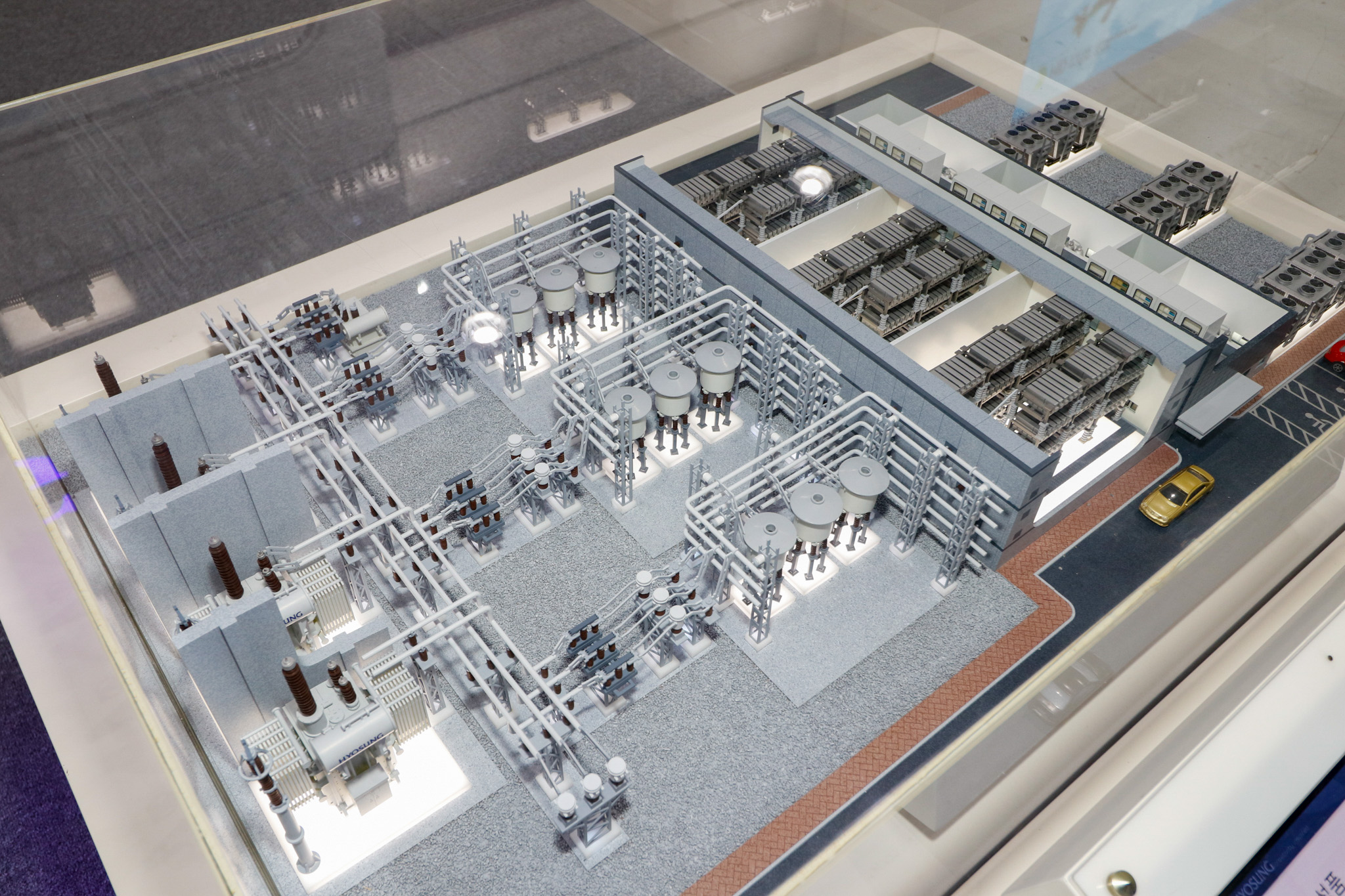

The Hyosung Heavy Industries exhibition hall also featured a miniature display of underground substation equipment installed near subway stations. Installing substation equipment underground not only saves space above ground, but is also convenient for areas where power lines are being buried.

▲ An underground substation equipped with Hyosung Heavy Industries equipment

The miniature depicted an underground substation equipped with Hyosung Heavy Industries' technology, including an 800kV 50kA 8,000A 2-break GIS and a 765kV single-phase 667MVA ultrahigh-voltage transformer. Above the substation, people were depicted going about their daily lives, illustrating the real impact of Hyosung Heavy Industries' technology on our lives.

▲ Miniature representing Hyosung Group's RE:GEN renewable energy ecosystem

In addition, there were displays of Hyosung Heavy Industries' environmentally friendly power generation equipment, such as the industry-leading Flow Battery stationary energy storage system and PV PCS equipment that enhances the stability of wind and solar power plants. Visitors could also explore corners that showcased the blueprints of Hyosung Heavy Industries' ESG development.

Becoming the world's No.1 through hard work and public interest

SIEF 2023 was a remarkable event, with a record 600 exhibition booths showcasing the current state of power and generation technologies and the keen interest in related industries. In particular, the Hyosung Heavy Industries exhibition attracted a lot of attention. Visitors ranged from industry professionals, including executives from companies such as LG Electric, to students from vocational high schools such as Sudo Electric Industrial High School, covering a wide range of ages and career stages. With a wide range of exhibits and heartfelt explanations, visitors were able to learn and experience more about Hyosung Heavy Industries.

▲ A Table summarizing the core essence of the Hyosung Heavy Industries brand

In the power industry, Hyosung Heavy Industries is expanding its customer infrastructure and gaining extensive experience in medium and large-scale projects. Through these efforts, Hyosung Heavy Industries is steadily building a diversified portfolio that can compete with the world's top brands in the power industry. It won't be long before Hyosung Heavy Industries' presence can be seen in power plants around the world. This was evident at SIEF 2023, where Hyosung Heavy Industries showcased its leap to becoming the world's No. 1 power industry solutions company.